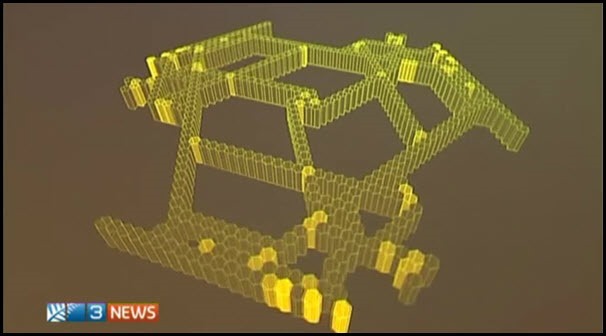

3D Printing of Honeycombs Helps Bees

Image source: 3news.co.nz

Have you ever wondered if bees get tired building their combs with the most intricate designs? Well, it seems they do and that’s where 3D printing technology enters to make it easy for the Queen Bee and her swarm. Beekeeper Richard Evatt states that the bees need to consume more honey, almost six to eight times more than the wax.

An artificial comb created by AUT University (Auckland University of Technology ) is similar to the ones that the bees build. This not only relieves the Queen Bee and her swarm of wasting their energy, it also offers the insects more time to make honey which would otherwise have been spent in building the comb. The comb simulated by the AUT University is created with the help of CAD (Computer-Aided Design) software. According to Mr. Evatt, the process of making honey is simplified as all the bees now need to do is store the collected nectar in the comb, make it moisture free and then there’s honey.

Designer Gerbrand Van Melle explains that the software, besides analyzing the sound of the inside of the beehive, also creates 3D objects simultaneously. The amazing factor that the 3D printer is able to achieve as far as honey making is concerned is that what approximately 60,000 bees achieve in a week is achieved by the 3D printer in a day. Bees are able to increase their output with reduced stress and in a shorter period of time.

It’s not only the bees that seem to be looking forward to this amazing technique as even the beekeepers find it highly cost and time efficient besides being commercially viable. However, one question that looms large before the designers is, which methods would help in the printing of the artificial comb?

A key factor that works in favor of 3D printing of the comb is that it caters to the fetish of the bees for precisely sized space having the accuracy that they need. This accuracy can only be achieved by the software.

Need a 3D model for your 3D printing project? Have a look at what we can do for you on our 3D modeling page, or message us now to discuss your project!

More power to your 3D printing ideas!