CALL TOLL-FREE >> 1-833-864-3907

CALL TOLL-FREE >> 1-833-864-3907

5000+ Projects

400+ Clients

Since 1986

Many of them have been buying from us for ten years and counting. Because we save them money and anxiety.

(Click on a link to view drawings)

| THE MAGNUM GROUP | OTHERS |

|---|---|

✅ If input information is missing or not clear, we ask for clarification. |

❌ They do not ask for clarification and try to start without it. |

✅ If a question occurs during the work in progress, we ask it immediately. |

❌ They stop working and do not proceed until you ask why they've stopped. |

✅ We provide regular status updates as part of our SOP. |

❌ They do not provide updates even if asked. |

✅ We respond to all messages within 24 hours. |

❌ They do not reply in 24 hours and often have to be reminded as well. |

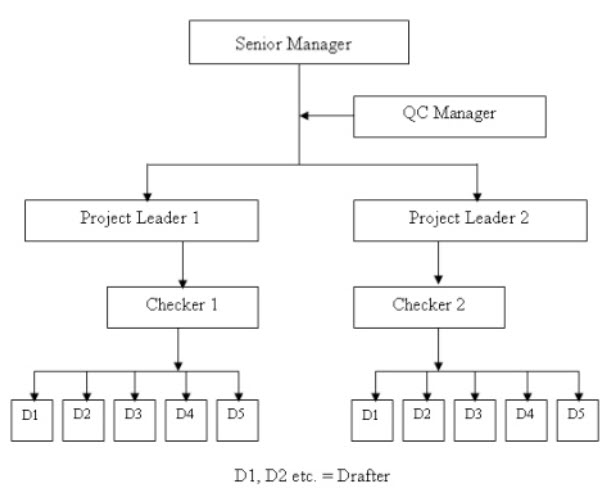

We organize teams to work in specific areas. We organize them on three bases; based on expertise in a particular CAD program, based on the assignments of a particular customer and based on the inflow of one-off, short assignments.

Regardless of the purpose of the team, its structure will be similar to that shown in the adjecent diagram. As can be observed from the diagram, work is checked at several levels by team members with increasing levels of expertise and responsibility, ensuring the high degree of accuracy our customers have come to expect from us.

| You tell us what you need done |

| ↓ |

| We mutually agree on price and delivery time |

| ↓ |

| You pay a deposit by PayPal to get the work started |

| ↓ |

| We keep you updated |

| ↓ |

| We send you screenshots of the completed drawings |

| ↓ |

| You pay the balance |

| ↓ |

| We send you the drawings |

No updates on drawing progress

Late replies to messages

Instructions not followed

Late delivery

Error-filled drawings

Your schedule is wrecked

You tear your hair out

Regular updates on drawing progress

Same-day replies to messages

Instructions followed carefully

On-time delivery

Error-free drawings

You're on schedule

Your hair is intact

We are deliberately digitally articulate so that you can get to know us and our CAD services better from the convenience of the web.

Click on the picture to go to our YouTube channel, where you can view specialist members of our CAD services team talk about their projects in exciting new areas and their opinions on various aspects of engineering and architectural design and drafting.

And don't be surprised if you also encounter the occasional rant about the local weather or environment… we might be CAD experts, but when all is said and done, we're human!!